Solution Confirmation

Technical Solutions: Technical and Quality Solutions Confirmation

Business Solutions: Terms and Price Solutions Confirmation

Technical Solutions: Technical and Quality Solutions Confirmation

Business Solutions: Terms and Price Solutions Confirmation

Prototype Cooperation, Prototype Confirmation;

Small Batch Cooperation, Small Batch Confirmation;

Batch Cooperation, Continuous Optimization.

Assembly and installation work must be done by training qualified personnel carefully;

Manufacturer is not responsible for any damage caused by incorrect assembly and installation;

In the planning phase, enough space should be left for maintenance and repair work of reducer in the future;

Before starting the assembly and installation work, must prepare the appropriate hoisting equipment;

If reducer (motor) is equipped with a fan, then you should leave enough space for it to inhale air;

Actuator nameplate instructions should conform with the power supply;

Gear should be intact (not damaged) in the process of transportation or storage;

Make sure following requests have been meeted:

For standard reducer: environment temperature 0 ° C ~ + 40 ° C

No harmful gas, steam, oil, acid, radioactive objects and etc;

For special type: transmission device is configurated based on environmental conditions;

Worm gear reducer: not applicable for self-locking reducer;

Apply too much adverse external moment of inertia, so as not to damage the reducer;

In order to guarantee good lubrication, must comply with the location requirements of order installation;

Be sure to pay attention to speed reducer (motor) warning and safety sign;

Use solvents to remove the flange, dirt or analogues on the surface of shaft and preservative;

Note: do not make solvent into oil seal's sealing lip, otherwise the solvent may get damaged on oil seal;

If the reducer is stored more than 1 year, the service life of bearing lubricant will be shorten;

If refill mineral oil or synthetic oil (CLPHC), and the amount are in conformity with the requirements of the installation position. The reducer is able to run at any time in this case. But, still have to check the oil level before starting;

In some cases, the filling is synthetic oil (CLPPG), oil level should be higher and correct oil level before starting.

Reducer (motor) can only be the installed according to the rules on flat, vibration and torsional support structure; During the installation process, cabinet foot and flange can't be tighten to avoid competing at the same time;

When using bolt or foundation block to fix reducer (motor) on the basis of concrete, there should be suitable grooves for reducer (motor);

When installation, please check whether the oil quantity is consistent with installation location, if the installation position changes, please adjust oil;

Install cut-through ventilator or turn on the ventilator transport rubber ring;

Don't crash and tap on the shaft end;

Vertical installation of the motor should have coverings to prevent liquid or other things to getr in;

When install junction box, make sure the cable service entrance point down.

Install and fix input and output drive components on the shaft of reducer (such as the coupling parts, etc.);

If these parts need to preheat before installation, please see the coupling in the file size figure about the right temperature;

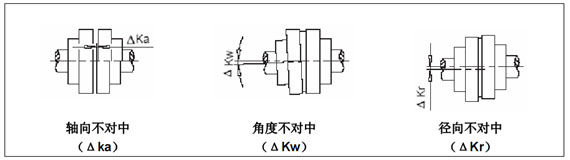

Shaft's unmatching may be caused by assembly or actual operation, such as thermal expansion, the deflection of shaft and insufficient stiffness of frame, etc.);

Coupling permitted misalignment ratio refers to the corresponding brand coupling instructions;

Misalignment should be done in the two axis perpendicular of the plane. Can use the ruler (of the radial) and feeler for misalignment;

Unless otherwise specified, these components can use induction heating method to preheat, can also use burner or heating furnace.

Work machine solid shaft should be equipped with the first part A flat key that comply with DIN6885 standard type, and there should be 322 DS type (threaded) center hole on its surface according to DIN standard;

Check if the reducer hollow shaft and solid shaft work machine have shaft seat and edge part damage; If necessary, use right tools to repair and clean;

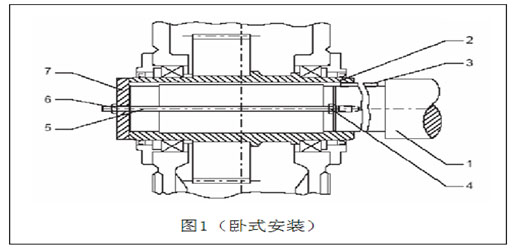

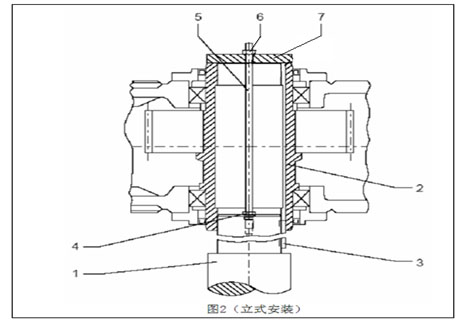

Install reducer with nut and screw , the reaction force is provided by reducer hollow shaft;

In addition to those nuts and screws shown in figure 1 and figure 2 , you can also use other types of devices such as a set of hydraulic lifting device.

Work machine solid shaft should be equipped with 322 DS type (threaded) center hole that comply with DIN standard;

Use integrated bushing for installation;

Use nut and screw to install speed reducer; Reaction force is provided by reducer hollow shaft;

Use loose sleeves to installation;br>

Take loose bushing on machine solid shaft, use a positioning device to firmly fix it in place, and then along the working machine solid shaft pull it back into the hollow shaft of the reducer (refer to figure 1, figure 2);

The outer surface of the hollow shaft of reducer can add grease on the contraction of the disc position;

Fasten bolts in sequence one by one, make sure all bolts are tightened;

Tighten the bolt until the inner ring and outer ring are in alignment.

Unscrew the oil plug, add correct type of lubricating oil to the place slightly above midline, and then install the plug;

No need to refuel speed reducer (motor).

Before starting must check and recorded for the following purpose:

(1) Oil level height

(2) Oil cooling or oil supply system of the pipe sealing

(3) The effectiveness of the shaft seal

(4) The rotating parts is not contact with other parts

For the first time starting of reducer (motor), if possible, should run for several hours no-load, if no abnormalities, can load gradually, then load up at the right time;

Speed reducer must be monitored in operation:

Oil temperature (in the process of continuous operation, reducer's design temperature is: continuous operation when using mineral oil, temperature is 90 ℃. At higher temperature, make sure to use synthetic oil. The highest temperature in short-period work can reach 100 ℃);

The running noise change;

The housing and shaft seal may leak;

The correct oil level height;

Repair failure must be conducted by customer service department happened in the . For the failures that happen after warranty period and unclear reasons, we suggest customer to contact our customer service department;

| Measures | Lead-time |

|---|---|

| Check oil temperature | Every day |

| Check the abnormal noise reducer | Every month |

| Check reducer leakage | Every month |

| Check oil level height | Every time before starting speed reducer |

| Check water percentage in oil | 400 hours after starting work |

| First oil change | 400 hours after starting, at least once a year |

| Followed oil change | Every 18 months or 5000 hours |

| Oil filter cleaning | Every 3 months |

| Screw ventilation valve cleaning | Every 3 months |

| Fan and fan cover and deceleration box cleaning | Clean according to requirements or at the same time with oil change |

| Check cooling coil scale | About every 2 years or at the same time with oil change |

| Check oil water cooler | At the same time with oil change |

| Check bolt fastening degree | After the first oil change, then once every two oil changes |

| Comprehensive reducer check | About every 2 years or at the same time with oil change |

| Failure | Reason | Measures |

|---|---|---|

| The noise in reducer fasteners | The loose of fasteners | Tighten bolt/nut to specified torque, replace damaged bolt/nut |

| Reducer's noise changes | Gear tooth get damaged | Contact customers service department to check all the gear, replace damaged bolt/nut |

| Bearing clearance large gap | Contact customer service department, adjust bearing clearance | |

| Broken bearing | Contact customer service department, replace damaged bearing | |

| Too high working temperature | High oil level of the inside box body | Check oil surface height, adjust if necessary |

| Long-used oil | Contact customer service department, check the last time oil change, replace if necessary | |

| Oil gets severely contaminated | Contact customer service department, change oil | |

| For reducer that equipped with lubricating oil cooling system, too low or too high coolant flow rate | Comprehensively regulate import and export of pipeline valves, check the free flow of water-cooling device | |

| Too high temperature for coolant | Check temperature and adjust according to demand | |

| Too low oil flow through water cooling device, reason: oil filter seriously blocked | Oil filter cleaning | |

| Oil pump mechanical failure | Contact customer service department, check whether the function of oil pump is normal or not, carry out repair or change the oil pump if necessary | |

| Reducer that is equipped with fan, fan cover's air inlet and/or body get seriously polluted | Fan cover and housing cleaning | |

| Reducer equipped with cooling spiral pipe: cooling spiral tube fouling inside | Contact customer service department, clean or replace spiral pipe | |

| Too high temperature in bearing | Too high or too low oil level in reducer box | Check oil surface height at room temperature and refueling on-demand |

| Long-used oil | Contact customer service department, check last time oil change | |

| Oil pump's mechanical failure | Contact customer service department, check whether the pump work normally or not, repair or change a new oil pump | |

| Broken bearing | Contact customer service department, check the vibration measuring data, check and change the bearing according to the need | |

| Bearing amplitude rise | Broken bearings | Contact customer service department, check the vibration measuring data, check and change the bearing according to the need |

| Damaged gear | Contact customer service department, check and change gear according to need | |

| Non-return device temperature is too high, check function failure | Damaged device | Contact customer service department, check and change non-return device according to need |

| Reducer leakage | Enclosure cover or joint sealing adverse | Check seal and connection, if necessary, change a new seal |

| Radial shaft seal failure | ontact customer service department, change new radial sealing ring | |

| Have water in oil | Have sundry in oil | Check if water does exist in oil, and laboratory analysis. |

| Lube oil cooler or the cooling spiral pipe failure | Contact customer service department, find out leakage position, change water cooler. | |

| Reducer machine ventilation when come up with cool air and condensation | Use the appropriate heat preservation material to guard the speed reducer, close air export or change its direction on structure | |

| Pressure alarm monitoring device, equipped with a pressure lubrication device, lubricating oil water cooling and air cooling is the reducer | Oil pressure<0.5bars | At room temperature check the oil level height, according to the need to go check the oil filter, according to the need to change, contact the customer service department, check the normal functioning of the oil pump, oil pump repair or replace |

| Double switching filter indicator emit alarm | Double switching filter clogging | According to the specification toggle switch filter will be blocked filter down and clean up |

| Oil supply system fault | See operating instructions on oil supply system description | |

| Motor does not start | Power interrupt | Check wiring, when need correct |

| Fuse fusing | Replace the fuse | |

| Motor protection device has action | Check motor protective device Settings are correct, when need discharge failure | |

| Motor contactor action, not in the control system failure | Check motor contactor control, when need troubleshooting | |

| Motor not starting or starting difficulty | Motor should be delta connection method, but it is a star connection | Correct wiring way |

| Voltage or frequency gravely deviates from the rating when starting at least | Try to improve the power supply; Check the power cord section | |

| Direction of rotation error | Motor wiring error | Swapping two phase line |

| Rumble and current consumption | Damaged winding | Motor must send professional repair shop repair |

| Rotor windings touch | ||

| Fuse fusing or motor protective device immediately action | Conductor short-circuit | Short-circuit eliminate |

| Motor short circuit | Professional repair shop discharge failure | |

| Connection wires error | Correct connection mode | |

| Electrical grounding short circuit | Professional repair shop discharge failure |